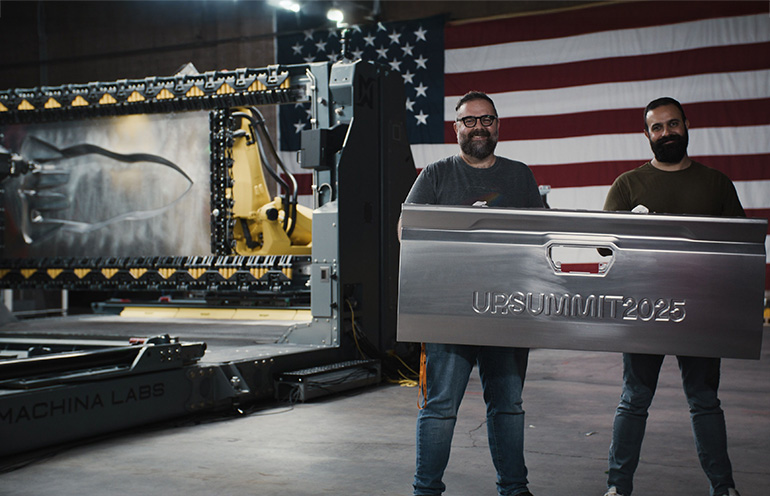

Machina co-founders Babak Raeisinia (left) and Edward Mehr (right) with a custom formed tailgate. Source: Machina Labs

Automotive body manufacturing typically involves rigid mass-production lines, with dies and presses forming sheet metal into panels and accessories. Machina Labs today announced a robotic approach that it said will enable vehicle makers to bring customized vehicles to market at mass-production prices.

“Traditional production tools are often massive, comparable in size to a small car and weighing over 20 tons,” stated Ed Mehr, co-founder and CEO of Machina Labs. “With our solution, the need for dedicated tooling per model variation is eliminated. That means lower project capital, less storage both in-plant and for past models, which today can last up to 15 years, and faster production changeovers.”

“The dies or molds to stamp out sheet-metal parts are very expensive and bulky,” he told The Robot Report. “They have to move around rails and cranes, and two-thirds of facilities are filled with these dies.”

Founded in 2019, Machina Labs said it is “building the next generation of intelligent, adaptive, and software-driven factories.” The Los Angeles-based company‘s RoboCraftsman platform integrates advanced robotics and AI-driven process controls to rapidly manufacture complex metal structures for aerospace, defense, and automotive applications.

“We started Machina Labs as a new paradigm of manufacturing, with cell-based matrix production,” Mehr said. “Our program can do different things — metal forming, trimming, and quality control — but forming is our core. With 200 to 300 of our systems, you have the equivalent of a data center for manufacturing using UGVs [uncrewed ground vehicles].”

Machina Labs modernizes sheet forming

The automotive customization and accessories industry is valued at $2.4 billion in 2024 for trucks alone, noted Machina Labs. However, conventional high-volume manufacturing limits the amount of variation in vehicles and the timeframe in which they can be changed.

The company said its RoboCraftsman platform and RoboForming technology enable a proprietary method of incremental sheet forming proven to deliver customized panels from sheet metal for ground and aerospace vehicles at high volume, high quality, and short lead times.

“Our process gets rid of the die,” Mehr explained. “Robots incrementally form the sheet into a shape. You can get parts significantly faster. The fastest you can change die making is like three months; with some complicated ones, it’s up to a year before you can get your first part. With us, you can get your first part in hours after the design is done. There are also certain metals that were not able to be formed at room temperature using traditional technologies, so we open up to new alloys like titanium or nickel alloys.”

In addition, the company claimed that its systems can streamline process flow within the factory. Current manufacturing models require separate storage, repackaging, and dedicated assembly lanes for custom parts. Machina said its systems provide on-demand part production in low volumes from cells near the assembly line, allowing for dynamic batching or broadcast-driven manufacturing – all without disrupting existing flows.

“The automotive market formed models around these time limits — they had to produce the same car over and over again to amortize the cost of dies and molds and keep the dies and inventory for 15 years to support them,” said Mehr. ‘We’re looking at a completely new market with customization. We did a topographic map of LA on the hood of one car.”

Toyota provides investment, pilot

“Our first market was defense, with high-mix, low-volume production of UAVs, aircraft, and missiles,” said Mehr. “But I’m a car enthusiast, and we were lucky to get connected with Toyota. We’re very good at making bespoke products, but there’s a lot to learn about standard operating procedures. We’ve spent a few years on this collaboration to understand upstream and downstream automotive processes.”

Machina Labs made its announcement today at UP.Summit alongside a pilot of the technology with Toyota Motor North America and a strategic investment from Woven Capital, Toyota’s growth-stage venture investment arm. The pilot project will apply Machina’s RoboForming technology to customize body panels, with the goal of bringing automotive-grade quality and throughput to low-volume manufacturing.

“We envision a future where customization is available for every Toyota driver,” said Zach Choate, general manager of production engineering and core engineering manufacturing at Toyota Motor North America. “The ability to deliver a bespoke product into the hands of our customers is the type of innovation we are excited about.”

“AI-powered manufacturing is transforming how products are designed and produced at scale,” added George Kellerman, founding managing director at Woven Capital. “Customers increasingly demand more personalized products, while engineers need faster, more cost-effective paths from concept to production without the constraints of traditional supply chains.”

Machina plans to spend the next year to continue learning how to integrate its systems into automotive production.

“We’re figuring out how to do a few thousand vehicles or even more,” Mehr said. “We’ve had electric cars and autonomous cars, and I think we’re now in the early stages of personalization. It’s a new category. People really want to express themselves, which is what car making was before Ford introduced mass production. It was only available to the rich, but now we can bring it back for everybody.”

The post Machina Labs uses robotics, AI to customize automotive body manufacturing appeared first on The Robot Report.