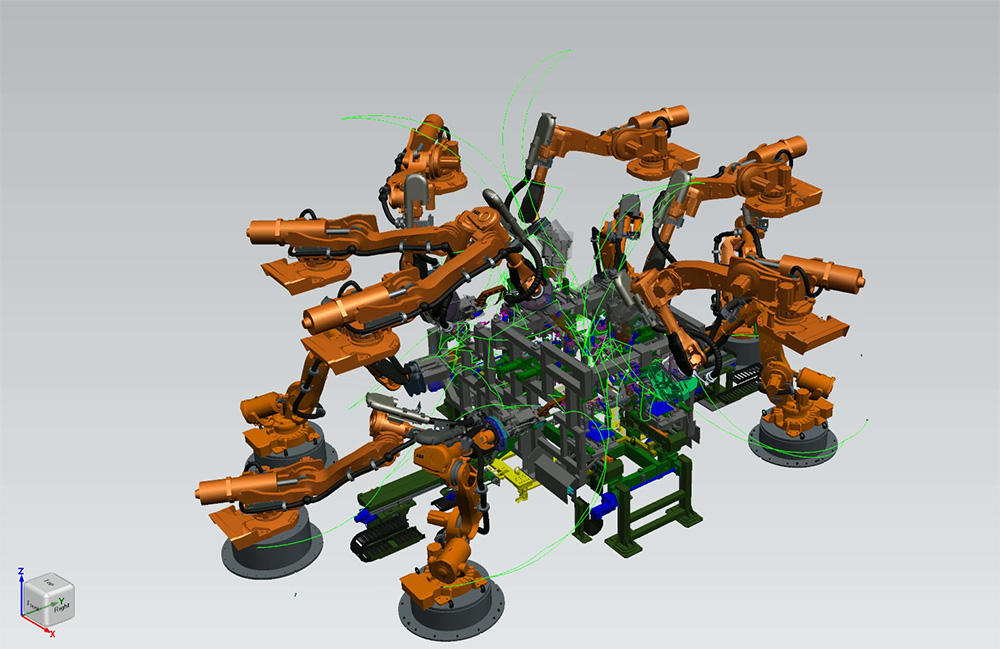

Realtime Robotics said its motion planning technology can accelerate the design and deployment of robotic workcells. | Source: Realtime Robotics

Realtime Robotics, a provider of robotic motion-planning software, today released two new direct integrations for Resolver. The company said Resolver is a cloud-based system that can accelerate the design and deployment of robotic workcells.

Now, users of Visual Components or Mitsubishi Electric’s MELSOFT Gemini 3D manufacturing simulation software can use Resolver‘s industrial AI without having to leave their preferred environment. These new integrations join the existing integration with Siemens Process Simulate, which was available at launch.

“Since launching Resolver commercially last month — following six months of intensive collaboration with automotive OEMs and their line builders and integrators across the U.S., EU, Japan, and China — we’ve seen momentum accelerate rapidly,” said Peter Howard, CEO of Realtime Robotics. “Two OEMs are already citing Resolver in their requests for proposals, while others are already using it as part of their internal standard workflows. This rapid acceptance is based on the consistent 15% to 40% cycle-time improvements users are enjoying.”

Resolver accelerates cycle times

Boston-based Realtime Robotics claimed that it is the leader in automated collision-free motion planning, control, and optimization for industrial robots. The company said it solves for cycle-time optimized motions, interlocks, multi-robot coordination, and real-time object detection and reaction.

Resolver is a cloud-based optimization engine that automates the most time- and labor-intensive parts of robotic workcell design, according to Realtime. This includes path planning, task allocation, sequencing, and layout validation.

“Whether engineering a brand-new production line or upgrading a single robotic workcell, Resolver empowers users to achieve superhuman cycle times,” asserted the company. ‘This results in faster builds, fewer errors, and validated designs in mere minutes. The longer Resolver runs, the more options it provides, shortening the cycle time until the desired outcome is reached.”

Realtime builds relationship with Visual Componenets

Realtime Robotics said its integration of Resolver with Visual Components is part of a larger partnership. Known as “the fastest way from concept to reality,” the Espoo, Finland-based company has built its reputation on intuitive, collaborative 3D simulation and robot programming tools. These are backed by a library of more than 3,500 components and 1,600 robot models.

The companies said they have seen growing traction for more complex use cases, such as large-scale automotive spot‑welding cells. “Combined with Resolver, Visual Components can now be used to solve cells of any complexity and size, and at remarkable speed,” Realtime said.

The companies are offering a joint trial of one month of Visual Components’ robot offline programming (OLP) software free when exploring the Resolver sandbox. A four-week extended trial is also available to those who mention “Realtime Robotics” and “Resolver” in the “How We Can Help” section.

Realtime is showing its new Resolver integrations, as well as an interactive demonstration of Resolver, at Booth 301, Hall B6 at Automatica this week in Munich, Germany.

Save now with early bird discount

The post Realtime Robotics announces two new direct integrations for Resolver appeared first on The Robot Report.