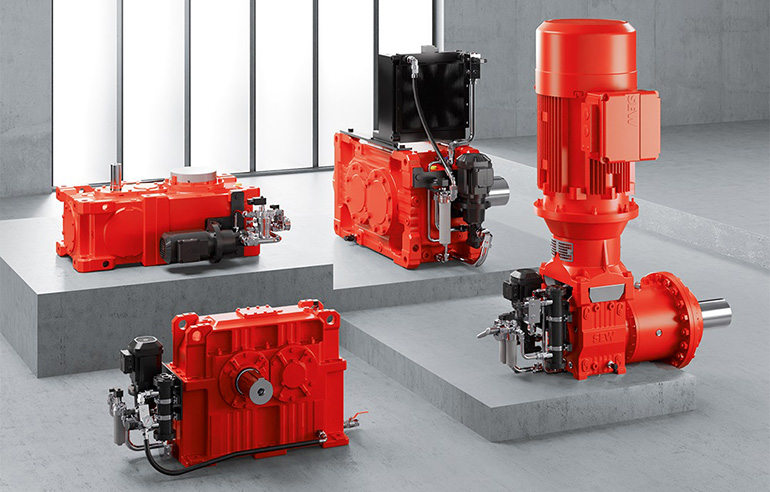

SEW-EURODRIVE said its new oil cooling and supply systems are assembled in South Carolina, shortening delivery times. Source: SEW-EURODRIVE

SEW‑EURODRIVE now offers external oil cooling and supply systems for heavy industry gearing with lead times as short as six weeks. These systems are engineered to support torque-dense gearboxes, where thermal limitations often determine gearbox size.

The company noted that the external lubrication systems are built and configured at SEW-EURODRIVE Heavy Industry Gearing (HIG) in Wellford, S.C., Previously available only through longer-lead global channels, these systems are now stocked and assembled in the U.S., eliminating delivery bottlenecks.

Founded in 1931, SEW-EURODRIVE is an industrial automation leader, with operations in more than 50 countries, 17 manufacturing plants, 92 assembly facilities, and over 21,000 employees. The Bruchsal, German-based company provides engineered systems for industries including automotive, food and beverage, pharmaceuticals, mining, steel, logistics, energy, and more.

New products keep systems stay cool for critical applications

As HIG drive systems grow more compact and power-dense, thermal management becomes essential, said SEW‑EURODRIVE. It claimed that its external lubrication systems address that challenge, with configurations that ensure oil is delivered, circulated, and cooled as needed for industrial applications.

The company said available systems include oil-to-air cooling (OAP1), oil-to-water cooling (OWP1), and pressure lubrication systems without cooling (ONP1). Each type is sized using SEW‑EURODRIVE’s thermal validation tools and can be gearbox-mounted or skid-mounted for flexibility in layout and maintenance access.

In addition, the new external lubrication systems are designed to support thicker startup oil viscosities up to 5,000 cSt, said SEW-EURODRIVE.

SEW-EURODRIVE offers modular and standard options

SEW‑EURODRIVE said its Oil Cooling and Supply Systems can be tailored to robot developers and machine integrators’ specific requirements. They include modular, sensor-ready features to support system reliability and monitoring.

Standard stocked options include:

• Duplex oil filters (25µm) — allows filter change during operation

• Electro-optical contamination pop-up indicator

• Oil manometer gauge

• Oil thermometer gauge

• Oil pressure switch

• Oil temperature switch — all to monitor the gearbox oil sump in real time

These standard options are in stock and ready to configure, according to SEW-EURODRIVE. Because these systems are assembled in the U.S., delivery times have been reduced from 14 to 20 weeks to as little as six weeks, the company said.

“With local assembly and standard stocked components, we can now deliver complete external thermal management solutions in six weeks—helping our customers get their HIG systems up and running faster and more reliably,” stated Austin Burdette, product manager at SEW‑EURODRIVE HIG USA.

The post SEW-EURODRIVE supports heavy industry gearing with fast turnaround appeared first on The Robot Report.