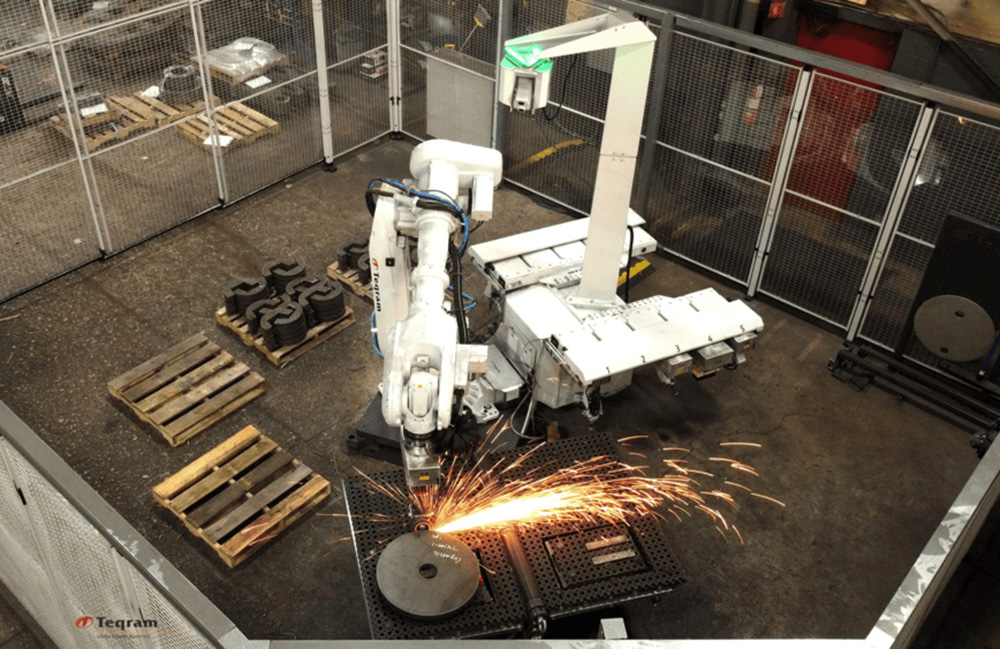

Teqram said the EasyGrinder performs autonomous robotic grinding for surface preparation Level SSPC-SP5/SP11. | Source: Teqram

Accurate Metal Products, or AMP, a steel processor and fabricator, this week announced it installed two AI-powered EasyGrinder robotic systems from Dutch manufacturer Teqram. This is the first time Teqram has deployed this system in the U.S.

“These machines help us maintain the high standards our customers expect, while making life easier for our skilled tradespeople,” said AMP owner Woody Alverson. “It’s not about replacing people — it’s about enhancing precision and freeing up time for more valuable work.”

Founded in 1995, AMP is a precision steel fabricator with ISO 9001 certification and two full-service Midwest locations. The Milwaukee-based company serves OEMs across several industries, including mining, energy, agriculture, and defense.

AMP’s in-house capabilities include oxy-fuel, plasma, and laser cutting, Blanchard grinding, abrasive blasting, and heat treating. It said the EasyGrinders are a natural addition to its technology portfolio.

Teqram targets physically demanding part of fabrication

Teqram said its EasyGrinder automates one of the most physically demanding stages of steel fabrication: cleaning and finishing flame- and plasma-cut parts. Using artificial intelligence and advanced 3D vision, the system requires no programming, claimed the Zwolle, Netherlands-based company.

EasyGrinder identifies parts and picks them up with magnetic grippers. It processes parts autonomously using the best-suited tools from its automatic tool changer, Teqram said. It can clean both sides of a part by flipping it with the integrated EasyFlipper. The system can remove slag and lead-ins, grind and round edges, and clean interior diameters.

Teqram said it is committed to transforming metal processing with AI-enhanced robotic systems that simplify automation. The company’s products include:

- EasyDebur, which can loan and unload any brand of deburring machine.

- EasyFlipper, which can turn or rotate heavy parts safely.

- EasyShotblast can load and unload shotblasting machines.

- EasyMillDrill can load and unload milling machines with workpieces up to 600 kg.

- EasyLevel, which can automate the loading and unloading of levelling machines for metal parts.

- EasyUnpacker can automatically load sheets for flatbed cutting machines, including the removal of scrap and unloading parts onto pallets.

- Bin Picking, which is used for recognizing and picking up different parts that have been randomly delivered to the robot. For example, randomly and unsorted placed parts in a bin.

AMP digitizes with EasyGrinder

AMP acquired the EasyGrinders through Automated Fabrication Systems LLC (AFS), Teqram’s partner for North America. With over 25 years of experience, AFS said it delivers systems that boost productivity, quality, and profitability for fabricators.

The EasyGrinder robots are now operating at AMP’s facilities in Milwaukee, Wis., and Rockford, Ill. The fabricator said the systems will play a vital role in its ongoing digital transformation strategy, supporting its commitment to delivering production-ready components with consistent quality and short lead times.

“This investment reflects our belief that technology and craftsmanship go hand in hand,” said Alverson. “At Accurate Metal, we’ll always prioritize quality — whatever it takes.”

The post Teqram deploys automated grinding robot in 2 states with AMP appeared first on The Robot Report.